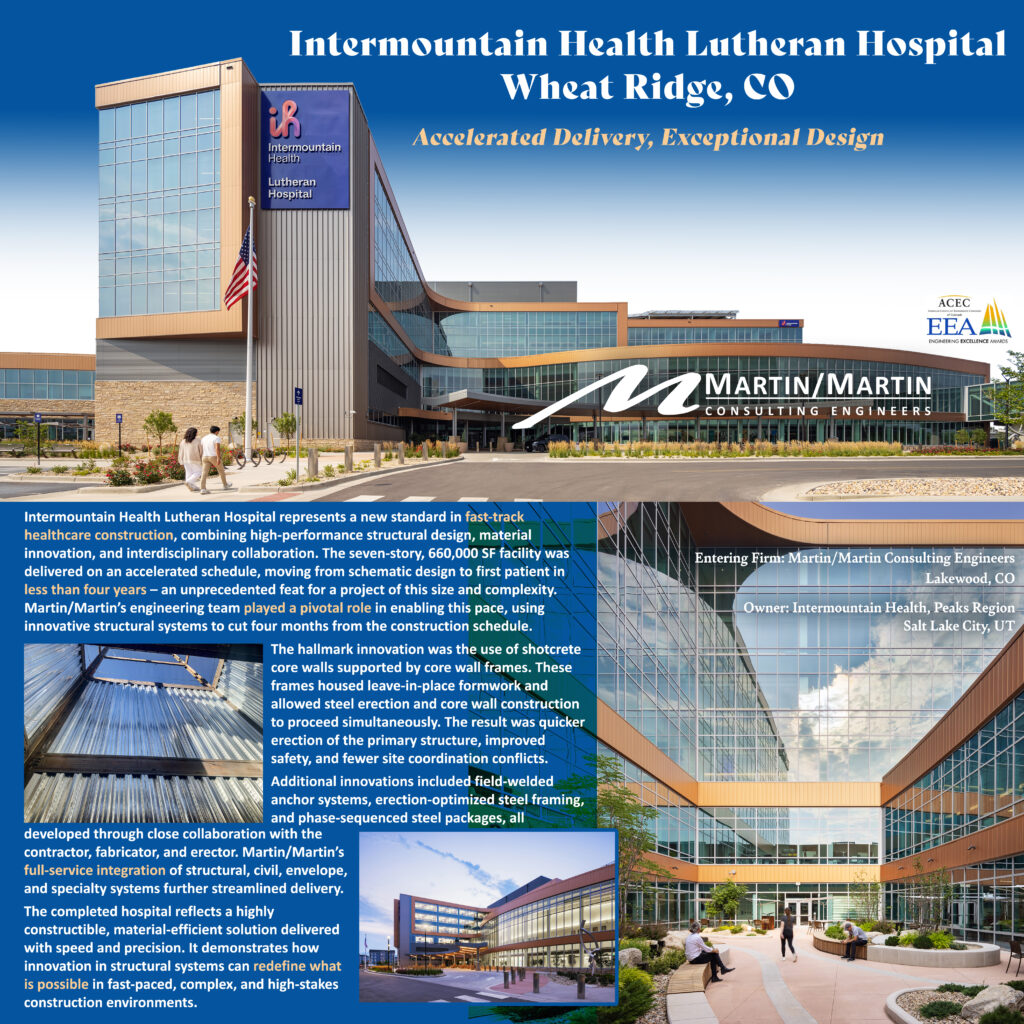

The Intermountain Health Lutheran Hospital project sets a new benchmark in fast-track healthcare construction through a bold combination of structural innovation, interdisciplinary collaboration, and a deeply integrated design approach. This seven-story, 660,000-square-foot hospital replaces a 70-year-old facility serving western Denver and was delivered in under four years from schematic design to first patient—a remarkable achievement given its size, scope, and complexity.

Martin/Martin’s most impactful innovation was the development and implementation of a unique shotcrete core wall system. By combining steel-framed core walls with vertically installed metal decking used as permanent formwork, this system enabled the simultaneous construction of structural steel and core walls—an unprecedented approach in hospital design. This strategy eliminated conventional formwork cycles, significantly reduced labor demands, and shaved approximately four months off the construction schedule. The result was an accelerated erection process, improved safety, and enhanced sequencing control for all trades on site.

The engineering team further advanced construction efficiency through innovations like fieldwelded anchor systems, phased steel mill order packages aligned with critical path elements, and steel detailing optimized for erection sequencing. These strategies were developed through close collaboration with the contractor (Barton Malow/Haselden JV), fabricator (Drake-Williams Steel), and erector (LPR Construction), demonstrating the power of early and deliberate coordination in delivering constructible, cost-effective solutions.

From a social and economic standpoint, the project responds directly to growing healthcare demands in the Denver region. Its expedited delivery ensures faster access to modern medical services, while Martin/Martin’s integrated engineering services—encompassing structural, civil, envelope, and fall protection systems—minimized coordination loops, waste, and overall environmental impact.

Despite significant technical complexity, including managing structural load sequences across multiple levels and coordinating the timing of shotcrete placement and temporary stability systems, the engineering team met all performance, safety, and scheduling requirements. Every design decision was intentionally aligned with the owner’s top priority: bringing the hospital online as quickly as possible without compromising quality.

In conclusion, the Intermountain Health Lutheran Hospital showcases how creative engineering and collaborative delivery models can redefine the boundaries of speed, constructability, and sustainability in healthcare construction. It stands as a replicable model for high-stakes projects requiring innovation, precision, and urgency.